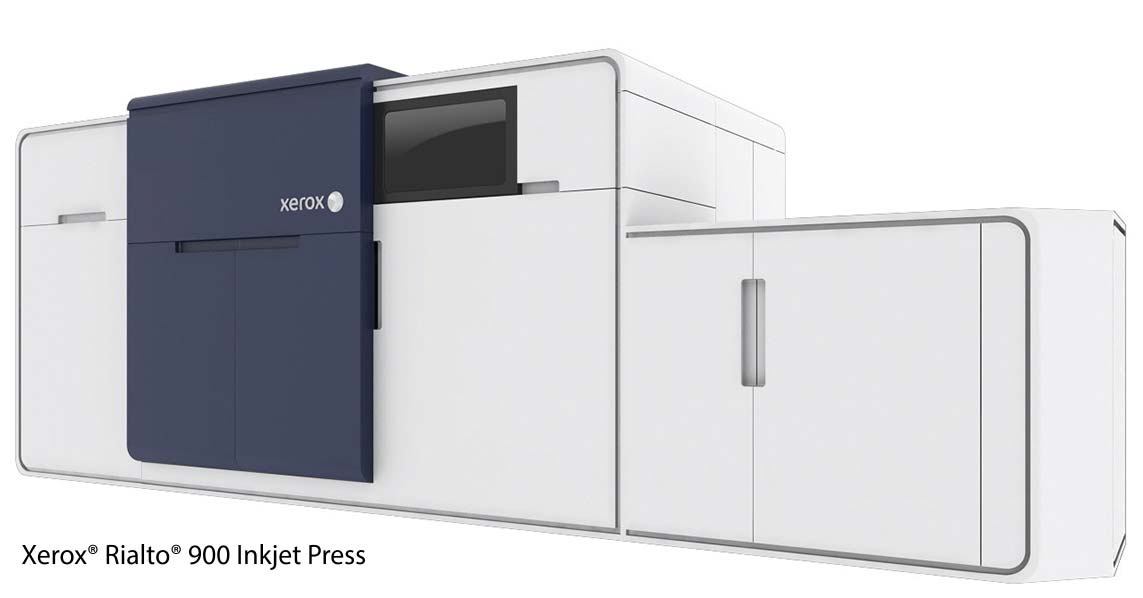

PM Solutions had a goal: Transform their operation by eliminating the cost and inefficiency of litho shell production. But in terms of economics and output quality, inkjet didn’t seem to cut it in the SMB market. Until Rialto.

Based just outside Edinburgh, Scotland in the UK, PM Solutions has been in business for 22 years. Although the business has evolved over the decades, today they focus primarily on direct mail and transactional print in small to medium-run quantities – adding up to an annual volume surpassing 30 million.

THE SITUATION

With hefty – and steady – annual growth leading to investment in a new, purposebuilt facility with a double shift pattern, business development head Brian Purves felt the time was right to make the transition to a white-paper-in solution. In addition to the profit-driving potential enabled by white-paper-in efficiency, he needed a solution that could cope with high-volume peak periods for his larger, regular customers. He also saw an opportunity to expand his SMB customer base with more streamlined production workflows and capacity.

THE CHALLENGE

After examining a number of competitive presses, Purves remained concerned about inkjet’s ability to match the quality expectations of his customers. Having recently purchased a Xerox® Colour 8250 Production Printer and Xerox® Versant® 80 Press – and finding both offered great service, success, implementation process and quality – he accepted an invitation to see Xerox® inkjets in action. Purves investigated the full line of Xerox® production inkjet presses – including the Xerox® Rialto 900, Xerox® Trivor® and Xerox® Brenva®. His qualms obliterated immediately by Xerox breakthrough image quality – having found Xerox white-paper-in output indistinguishable from his current litho shells – all that remained was choosing the right member of the Xerox® production inkjet family.

THE SOLUTION

“We were operational within 10 days – and more importantly, the Xerox team stayed for another week to help us through any issues.” – Brian Purves Business Development, PM Solutions

THE RESULTS

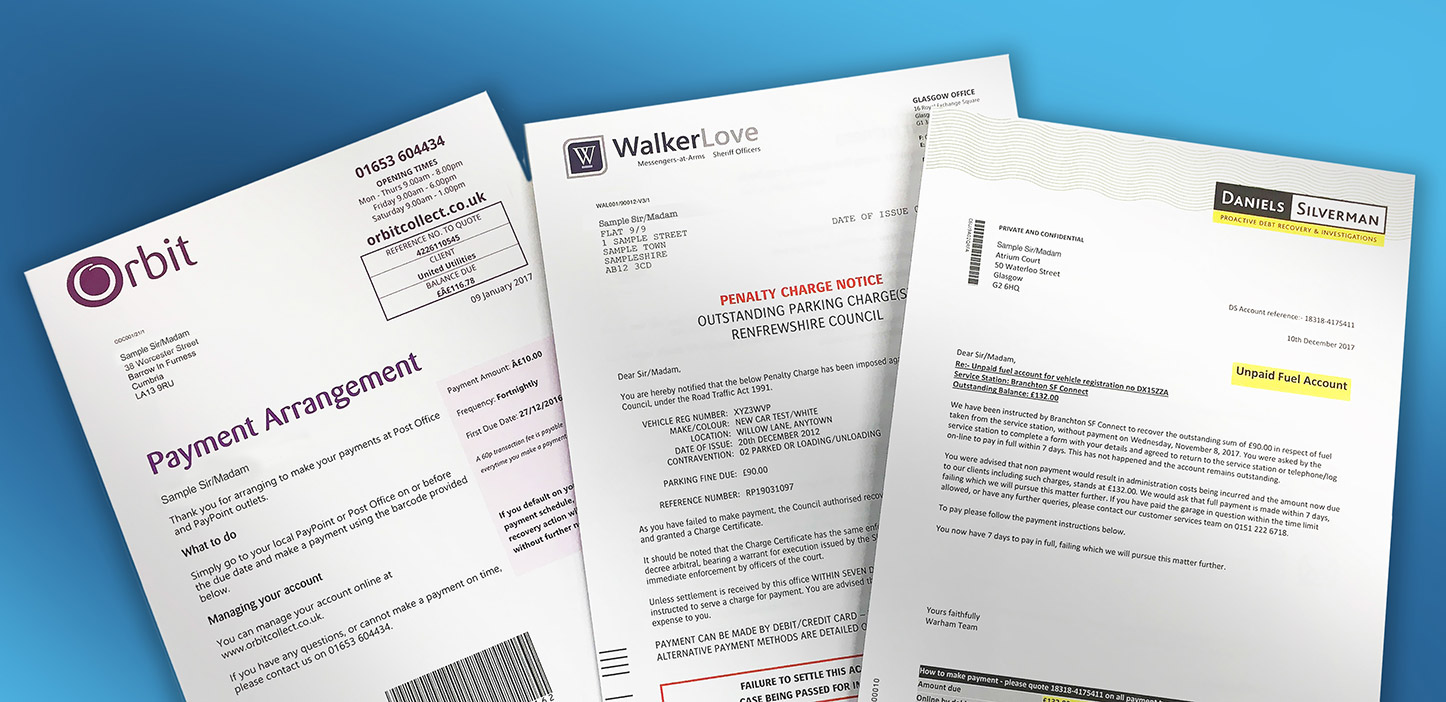

In addition to productivity enabled by the transition to transition to Lite-paperin technology and workflows, Purves is happy to report that none of his clients have noticed the change. “The output is indistinguishable from offset,” he said. “Of course, if they asked, we’d tell them, but no one is questioning it. That’s the quality we were after and that we found with Rialto®.”

In addition to higher quality in a digital, white-paper-in workflow, PM Solutions has gained efficiencies and savings by selecting a preferred stock for their Rialto. They’ve selected a lightly coated 90 and 100 gsm inkjet stock called Crown Van Gelder Letsgo High Performance supplied by Antalis in the UK. It works perfectly for inkjet output – and buying it in rolls has reduced production costs and provided an additional measure of consistency for customer needs.

In terms of productivity, the growth has been transformational. PM Solutions’ Rialto came bundled with Xerox® FreeFlow® Core, and Purves has been able to use it to speed up the processing of files to print.

“If I get a job from a client, I want to be able to come back to the client now – not four hours later – to let them know it will work.”

With FreeFlow Core, Purves uses their Xerox® Versant® 80 for immediate proofing, and then moves to imposition and distribution to the appropriate press – cutting up to 75% out of the usual wait time to get a job on the press. As volume increases, Purves said, this will be critical to maintaining growth without adding costs. Even as PM Solutions makes their strategic shift to roll-fed, white-paper-in to grow business and unleash growth potential, they are are committed to maintaining a balanced operation fine-tuned to their their market needs. In fact, they recently added a Xerox® Versant 3100 Press (a sheet-fed SRA3 digital press) to their portfolio.

Still, Purves sees a need for an additional Rialto within the coming year – spurred in part by data-handling regulations in the form of GDPR, the new data compliance programme that takes effect across most of Europe on May 25, 2018.

“Easy operation, consistent quality and speeds and capabilities that fit our market,” Purves said. “That sums it up. And we appreciate the partnership.”

Find out more about Xerox® Rialto® 900 Inkjet Press at www.xerox.com/rialto.

Latest Posts

May 27, 2021

May 19, 2021

May 02, 2021

APR 23, 2021

MAR 11, 2021

JAN 21, 2021

NOV 13, 2020

JULY 05, 2020

JULY 04, 2020

June 29, 2020

June 26, 2020